Wedge Wire Screw Press Machine

Wedge Wire Screw Press Machine: Your Trusted Partner in Advanced Process Dewatering

Gemach Technologies Private Limited (GTPL) is recognized as a leading Manufacturer of high-performance Wedge Wire Screw Press Machines in Gujarat, India. Since our inception, our commitment to exceptional quality and innovative design has propelled us to the forefront of a highly competitive market, both domestically and internationally.

In industries where efficient solid-liquid separation and reliable dewatering are critical, our Wedge Wire Screw Press Machines deliver unparalleled performance. We continuously integrate new ideas to provide highly durable and robust solutions designed to simplify your operations, reduce waste, and maximize resource recovery.

Unmatched Performance for Demanding Industries:

Our Wedge Wire Screw Press Machines are engineered to excel in diverse industrial applications, including:

- Food Processing: Optimizing dewatering for fruits, vegetables, beverages, and food waste.

- Paper Pulp: Efficiently dewatering paper pulp and fibrous materials.

- Distillery & Beverages: Separating spent grains, fruit pulp, and other residues.

- Wastewater Treatment: Effective sludge dewatering for municipal and industrial ETP/STP.

- Agriculture & Biogas: Dewatering animal manure, biogas slurry, fermented agricultural waste, and more.

- Chemical & Pharmaceutical: Reliable solid-liquid separation and dewatering in process streams.

- Mining & Metallurgy: Desludging, dehydration in coal preparation, and tailings management.

- Biomass: Dewatering biomass for energy production.

Partner with Gemach Technologies Private Limited:

Our unwavering commitment to quality, dedication, and hard work has secured our top market position. Gemach Technologies Private Limited looks forward to partnering with you to deliver premium quality dewatering solutions at the best prices.

When considering a Wedge Wire Screw Press Machine, factors we meticulously consider include:

- Material Properties: Type, solid content, viscosity, and abrasiveness of your specific material.

- Capacity Requirements: The desired volume of material to be processed per hour.

- Desired Cake Dryness: Your target moisture content for the discharged solids.

- Specific Application: Tailoring the machine to your unique industry and process needs.

- Material of Construction (MOC): Ensuring the right grade of stainless steel for optimal corrosion resistance and hygiene.

Key Components & Their Function:

- Screw Conveyor (Auger): The robust central rotating element that continuously compresses and conveys the material. Its precisely engineered design (pitch, taper, number of flights) gradually decreases internal volume, building pressure for efficient dewatering.

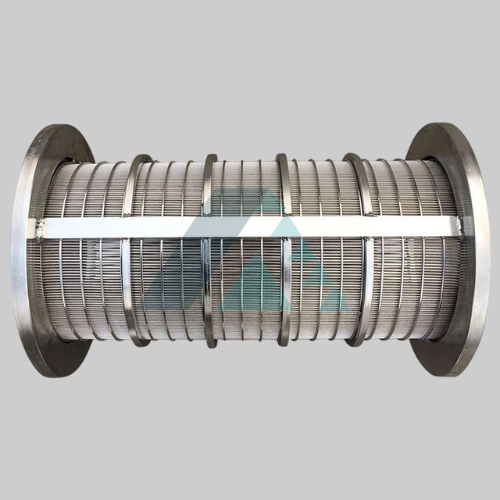

- Wedge Wire Screen: The crucial filtration medium. This cylindrical or conical screen is made of V-shaped or triangular wires welded onto support rods. This unique design creates continuous, precise slots that are wider on the inside and narrower on the outside. This innovative V-shape is the key to preventing clogging, allowing particles that pass the narrow opening to freely exit, significantly reducing downtime.

- Housing/Casing: Encloses the screw and screen, meticulously designed to collect the separated liquid (filtrate).

- Drive System: A powerful motor and gearbox ensure the screw rotates at a controlled, often slow speed, optimizing energy consumption.

- Back-Pressure Device: Located at the discharge end, this adjustable mechanism controls the resistance, allowing you to fine-tune the final dryness (cake consistency) of the discharged solids.

Understanding the Innovation: How Our Wedge Wire Screw Press Works

A Wedge Wire Screw Press Machine is a sophisticated industrial equipment designed for continuous solid-liquid separation and dewatering. Its ingenious design leverages a rotating screw (auger) within a specialized wedge wire screen to achieve superior separation.

The Working Principle: A Continuous Dewatering Cycle

- Feeding: The material (slurry, sludge, pulp, etc.) is fed into the machine’s inlet hopper.

- Conveying & Initial Dewatering: A slowly rotating Archimedean screw transports the material along the inside of the cylindrical wedge wire screen. Gravity and initial pressure from the screw cause initial liquid drainage through the wedge wire slots.

- Compaction & Further Dewatering: As the material moves along the screw, the decreasing volume and narrowing gaps between the screw and screen generate increasing pressure. This intense squeezing action forces more liquid through the fine slots of the wedge wire.

- Liquid Separation: The V-shaped wires of the screen ensure that liquid (filtrate) passes through efficiently while retaining solid particles. The unique design actively minimizes clogging. The separated, clearer liquid is then collected.

- Solid Discharge: The dewatered solids, now a “cake” with significantly reduced moisture content, are continuously discharged from the outlet, with their dryness controlled by the adjustable back-pressure device.

- Screen Cleaning: Many of our models incorporate integrated cleaning mechanisms (e.g., spray nozzles or internal scrapers) to ensure consistent screen performance and prevent blinding.

Core Advantages of Our Wedge Wire Screw Press Machines:

- Exceptional Dewatering Efficiency: Achieves high dry solids content in the discharged cake, minimizing disposal costs and maximizing resource recovery.

- Unrivaled Non-Clogging Design: The V-shaped wedge wire significantly reduces clogging compared to conventional filter media, ensuring continuous operation and less downtime.

- Low Energy Consumption: Operates at low rotational speeds, leading to substantial power savings compared to centrifuges or other dewatering technologies.

- Robust Durability & Low Maintenance: Simple design with fewer moving parts reduces wear and tear. Constructed from robust, corrosion-resistant stainless steel (SS 304, SS 316, SS 316L for 100% body parts, conveyor screw, hardware, and valves) for extended lifespan and easier maintenance.

- Versatility: Can handle a wide range of materials with varying consistencies, including fibrous, sticky, or oily sludge, with customizable slot sizes.

- Compact Footprint: Often requires less space than traditional dewatering equipment (e.g., belt presses, Multi Disc Screw Press, Volute Screw Press), optimizing your facility layout.

- Minimal Water Usage: Requires little to no wash water for the screen, contributing to water conservation.

- Continuous Operation: Designed for high-volume, continuous dewatering, making them ideal for large-scale industrial applications.

Ready to revolutionize your dewatering process with superior efficiency and reliability?

A Wedge Wire Screw Press Machine is a mechanical dewatering system that separates liquids from solids in organic or fibrous materials using a rotating screw and wedge wire screen. It is widely used in agriculture, food processing, biogas plants, and industrial waste management.

The wedge wire screen acts as a filtration surface that allows liquids to pass through while retaining solids. Its self-cleaning design minimizes clogging and ensures high durability and consistent performance.

-

-

Cow dung and other livestock manure

-

Biogas plant slurry

-

Food waste and kitchen waste

-

Fruit and vegetable pulp

-

Industrial sludge

-

Organic compost materials

-